Improved bridging behavior when dealing with multiple overlapping models.Bridging toolpaths will now be added, even when using concentric external fill patterns.New intelligent bridging algorithms utilize the model topology to automatically select the best bridging toolpaths.Print time estimates have been greatly improved by simulating the actual behavior of the printer firmware for increased accuracy.Improved priming sequences ensure that a tool is always primed at the beginning of each layer during multi-extrusion prints.New Prime Pillar and Ooze Shield construction provides better stability, improved bonding between layers, and reduced material contamination.Prime Pillar and Ooze Shield have been upgraded to fully support up to 6 separate extruders.Numerous additional bug fixes and stability improvementsĬlick here to read more about Version 4.1 and all of the new changes.Resolved several issues related to single extrusion toolpaths in thin wall regions.

Fixed a bug that had impacted bridging perimeter placement with some specific models.Fixed a bug related to support structures of duplicated models.Fixed a bug with retractions when the “force retraction between layers” option was disabled.Resolved an issue for more consistent retraction sequences when the “perform retraction during wipe movement” option is enabled.Updated skirt and brim placement so that they stay closer to the model outline for improved adhesion.Several improvements to the avoid crossing outlines behavior for more efficient travel paths between different areas of the print.Improved solid layer placement to create high-quality top solid layers.Improved seam locations for corkscrew printing mode (vase mode) using the start point options defined on the Layer tab.Significantly improved corkscrew printing (vase mode) transitions to create smooth spiraling outlines without any added artifacts.These mini PCs only consume 5-10 watts instead of a laptop that uses ☘0 watts," he writes in his Github profile. "It prints smoother than using a laptop running a bunch of other services not needed for printing and it draws much less power. Walter Schreppers, an engineer from Belgium, developed an app called Printerface (not to be confused with the above-mentioned Pronterface) that allows makers to control their printers through a web connection and calls out the fact that it's not just portability that makes the Raspberry Pi an idea choice for 3-D printers, but efficiency and environmental friendliness as well.

#Simplify 3d and repetier server software

While 3-D printer software is now attracting people with financial motives, the hacker era is far from over. Combined with the new Raspberry Pi camera and a little hacking the OctoPrint could be set up to automatically record timelapse videos of every print job, push them to YouTube, and create the first channel featuring nothing but 3-D prints.

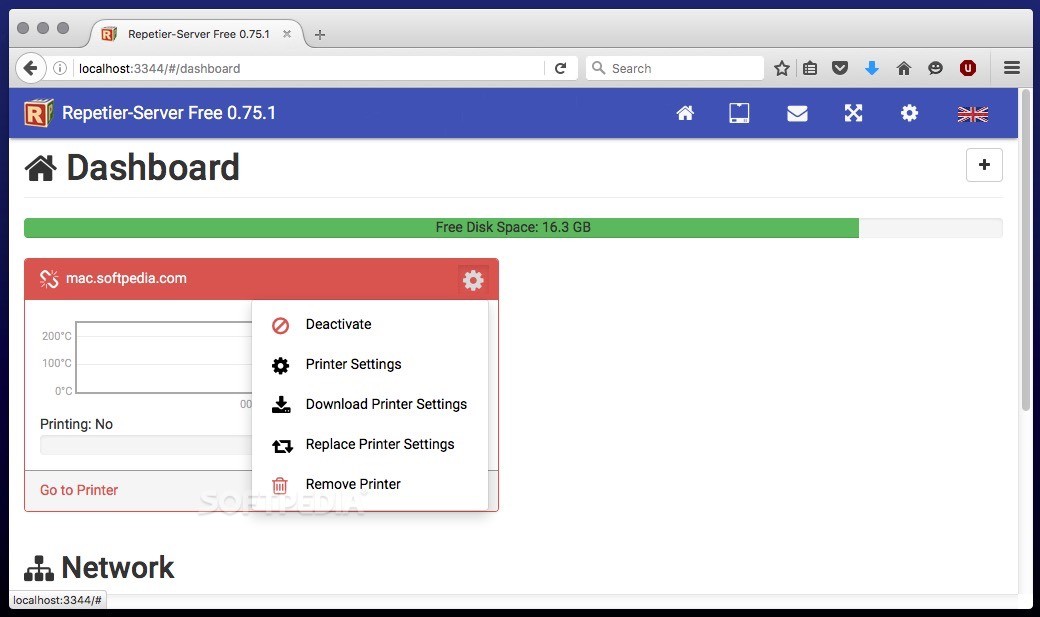

It can also do some fun things like create time lapse movies of parts being produced. OctoPrint has the same basic features as Printrun and Repetier - it can prepare jobs for printing, preview G-Code, and monitor the progress of print jobs. OctoPrint brings a little fun to an often frustrating process. Right now I am saving everything to my Dropbox account and just downloading the G-Code files on the Pi." "I am using my main computer to do the slicing of the STL files to generate the gcode. "I just wanted to make a self-contained system that was easily transportable," says Bales.

#Simplify 3d and repetier server code

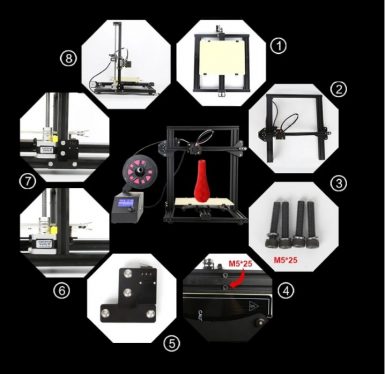

So he tricked out his Prusa Mendel RepRap with a Raspberry Pi, a 7-inch touchscreen tablet, and some code from Github. 3-D printing technology felt futuristic, but leaving a laptop attached to a printer for the duration of a modest five-hour print job seemed as dreadful as history class. He got into building a RepRap while acting as president of his engineering class. Zachary Bales is an undergraduate studying electrical engineering and physics at Cal State Long Beach. While most people still have trouble setting up an inkjet printer on a wireless network, a group of intrepid IT hackers are making big strides with far more advanced machines, using the tiny Raspberry Pi microcomputer to untether laptops from their 3-D printers.

0 kommentar(er)

0 kommentar(er)